Protective film bonded Detailed operating essentials

Release date:2016/6/13 17:05:45Origin: HUNGTECHViews:

1. For best results, the surface must be clean and dry. General Recommendations cloth dampened with a 1: 1 ratio of IPA (isopropyl AlcohoI Sundanese-propanol) and a mixture of water, wipe the surface clean post, until the surface is completely dry. (Note: Before using the IPA, please refer recommendations Precautions This solvent).

2, PE protective film is bonded to the surface of the material to the drum or other means (blade) to impose an average of about 15psi (1.05 Gongjin / cm2) of pressure to effectively fit.

3, follow the protective film from the point to the line to surface contact with the bonding surface bonding method. Artificial plastic bonded manner or roller blade to a solid and uniform pressure gluing, make sure that pressure is applied to the adhesive surface, only to make the glue stick and was contacted in order to avoid air covering them.

4, PE protective film release paper tear-off, if the previous steps to ensure that no air between the glue and be affixed, and then will need to fit the material paste, the same pressure to impose 15psi to make it effective stickers, if you want to remove air bubbles, it is recommended to increase the pressure to the article to bear the limits of the upper limit. Recommended operating conditions 15psi, 15 seconds.

5, the proposed construction of the ideal temperature is between 15 ℃ to 38 ℃, do not lower than 10 ℃.

6, to make the use of the protective film to save still has stable quality, the proposed storage environment of 5 21 ℃ (Y70 relative humidity.

7, it is recommended to use no substrate protective film, the shape of the cutting edge during machining do not contact with the protective film, in order to avoid the adhesion situation.

中文

中文 English

English Vietnamese

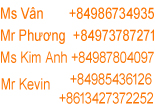

Vietnamese Email

Email Hot line

Hot line