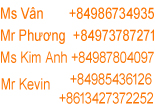

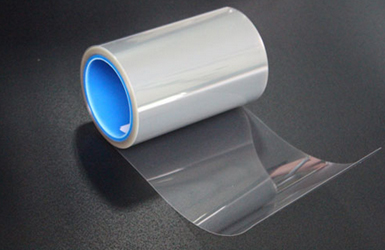

PET - Polyethylene terephthalate, Chemical composition is COC6H4COOCH2CH2O ,It is characterized by high temperature resistance, good printing, easy processing, high voltage insulation, fire prevention can pass 94 VTM - 2 certification, UL certification through SGS environmental protection, ROSH certification, based on polyethylene terephthalate as raw material, adopting legal system into thick slices, then through two-way stretch film material. It is a colorless, transparent, glossy film, good mechanical properties, high rigidity, hardness and toughness, durability, friction resistance, high temperature and low temperature resistance, chemical resistance, oil resistance, good air tightness and sweet, is one of the permeability resistance of composite film base material.

PET polyester film has excellent physical and chemical properties and dimensional stability, transparency, recyclability, which can be widely used in magnetic recording, photographic materials, electronics, electrical insulation, industrial film, packaging decoration and other fields

3 layer transparence PET film | ||||||||

Protect layer | Thickness | Liner | Adhesive | Adhesive types | Temperature range | Color | Features and applications | |

μm | μm | μm | g/25mm | ℃ | ||||

50 | 125 | 50 | 10~28 | Acrylic | -40~120 | Transparence | characteristic: High purity, high transparency, strong and stable glue appressed good effect use: Various control terminal protective glass panel, mobile phones, DV, tablet computers, navigation systems and other screen film. With a scratch-resistant, anti-burst and so on. More cost-effective than similar products | |

PE | PET | PET | 25 | 1~28 | Silicone | -40~120 | high transparency | |

1~28 | Silicone | -40~120 | High transparent scratch-resistant | |||||

1~28 | Silicone | -40~120 | Scrub | |||||

1~28 | Silicone | -40~120 | high transparency | |||||

1~28 | Silicone | -40~120 | Diamond | |||||

PET film ( no adhesive) | |

Thickness (μm) | 30,40,50,60,80,100,125,150,188 |

1 layer transparence PET film | |||||

Thickness | Adhesive | Adhesive types | Temperature range | Color | Features and applications |

μm | g/25mm | ℃ | |||

30 | 10~100 | Acrylic | -40~120 | Transparence | Characteristic: PET substrate moderate hardness, a wide range of thickness, Adhesive stable, clean and high, look no bubbles, peeling force is very smooth, no frustration, no noise.

It can be widely used in various types of precision display main material, the light guide plate, glass, electronic screens and other die-cutting industry, it can be used for die-cutting waste discharge Fucai. Temperature resistance: Stickers PET sheet, PC boards and other plates 150 ℃, 24 hours without unglued. |

40 | 10~120 | Acrylic | -40~120 | Transparence | |

50 | 10~270 | Acrylic | -40~120 | Transparence | |

60 | 10~270 | Acrylic | -40~120 | Transparence | |

80 | 10~270 | Acrylic | -40~120 | Transparence | |

100 | 10~270 | Acrylic | -40~120 | Transparence | |

125 | 10~270 | Acrylic | -40~120 | Transparence | |

150 | 10~270 | Acrylic | -40~120 | Transparence | |

188 | 10~270 | Acrylic | -40~120 | Transparence | |

30 | 1~28 | Silicone | -40~180 | Transparence | |

40 | 1~28 | Silicone | -40~180 | Transparence | |

50 | 1~28 | Silicone | -40~180 | Transparence | |

60 | 1~28 | Silicone | -40~180 | Transparence | |

80 | 1~28 | Silicone | -40~180 | Transparence | |

100 | 1~28 | Silicone | -40~180 | Transparence | |

125 | 1~28 | Silicone | -40~180 | Transparence | |

150 | 1~28 | Silicone | -40~180 | Transparence | |

188 | 1~28 | Silicone | -40~180 | Transparence | |

2 layer transparence PET film | ||||||

Thickness | Liner | Adhesive | Adhesive types | Temperature range | Color | Features and applications |

μm | μm | g/25mm | ℃ | |||

30 | 25~75 | 10~100 | Acrylic | -40~120 | Transparence | Characteristic:Product stability, can not afford to powder when punching, dimensionally stable base, products for punching various shapes, the viscosity of high, medium, low viscosity, no adhesive residue, inner layer stress, strong,etc.. use:Mobile phone lenses, surface protection film to protect the touch screen manufacturing process, after forming a temporary carrier optoelectronic materials and other accessories when Polaroid, LCD optical lenses, liquid crystal display panel manufacturing process. Has the advantage of cost-effective. |

50 | 25~100 | 10~270 | Acrylic | -40~120 | Transparence | |

60 | 25~125 | 10~270 | Acrylic | -40~120 | Transparence | |

70 | 10~270 | Acrylic | -40~120 | Transparence | ||

90 | 25~75 | 10~270 | Acrylic | -40~120 | Transparence | |

100 | 10~270 | Acrylic | -40~120 | Transparence | ||

125 | 10~270 | Acrylic | -40~120 | Transparence | ||

30 | 25~75 | 1~28 | Silicone | -40~180 | Transparence | |

50 | 25~100 | 1~28 | Silicone | -40~180 | Transparence | |

60 | 25~125 | 1~28 | Silicone | -40~180 | Transparence | |

70 | 1~28 | Silicone | -40~180 | Transparence | ||

90 | 25~75 | 1~28 | Silicone | -40~180 | Transparence | |

100 | 1~28 | Silicone | -40~180 | Transparence | ||

125 | 1~28 | Silicone | -40~180 | Transparence | ||

4 layer transparence PET film | |||||||||

Protect layer | Thickness | Liner | discharge layer | Adhesive | Adhesive types | Temperature range | Color | Features and applications | |

μm | μm | μm | g/25mm | g/25mm | ℃ | ||||

50 | 125 | 50 | 50 | 10~28 | Acrylic | -40~120 | Transparence | Robot four posts dedicated film protective film characteristic: Having a high purity, high transparency, glue and stability, appressed good advantage effect, scratch and so on. use: Various control terminal protective glass panel, mobile phones, DV, tablet computers, navigation systems and other screen film. With a scratch-resistant, anti-burst and so on. More cost-effective than similar products | |

PE | PET | PET | 25 | PE/PET | 1~28 | Silicone | -40~120 | high transparency | |

1~28 | Silicone | -40~120 | High transparent scratch-resistant | ||||||

1~28 | Silicone | -40~120 | Scrub | ||||||

1~28 | Silicone | -40~120 | high transparency | ||||||

1~28 | Silicone | -40~120 | Diamond | ||||||

High-temperature PET film (Golden) | |||||||

Layer | Thickness | Liner | Adhesive | Adhesive types | Temperature range | Color | Features and applications |

μm | μm | g/25mm | ℃ | ||||

Single | 50 | / | 10~100 | Silicone | -40~220 | GoldenTransparence | Characteristic: Products of high stability, high temperature performance. Surface protective film applied to machine lenses, Polaroid, LCD optical lenses, LCD panel touch screen when the process. |

60 | / | 10~270 | Silicone | -40~220 | GoldenTransparence | ||

Double | 50 | 25,30 | 10~100 | Silicone | -40~220 | GoldenTransparence | Characteristic: Products of high stability, high temperature performance. Surface protective film applied to machine lenses, Polaroid, LCD optical lenses, LCD panel touch screen when the process. |

60 | 25,30 | 10~270 | Silicone | -40~220 | GoldenTransparence | ||

High-temperature PET film (Gray ) | |||||||

Layer | Thickness | Liner | Adhesive | Adhesive types | Temperature range | Color | Features and applications |

μm | μm | g/25mm | ℃ | ||||

Single | 50 | / | 3~100 | Silicone | -40~220 | Transparence | Characteristic: Products of high stability, high temperature performance. Surface protective film applied to machine lenses, Polaroid, LCD optical lenses, LCD panel touch screen when the process. |

60 | / | 3~100 | Silicone | -40~220 | Transparence | ||

70 | / | 3~100 | Silicone | -40~220 | Transparence | ||

100 | / | 3~100 | Silicone | -40~220 | Transparence | ||

Double | 50 | 25,30,50 | 3~100 | Silicone | -40~220 | Transparence | Characteristic: Products of high stability, high temperature performance. Surface protective film applied to machine lenses, Polaroid, LCD optical lenses, LCD panel touch screen when the process. |

60 | 25,30,50 | 3~100 | Silicone | -40~220 | Transparence | ||

70 | 25,30,50 | 3~100 | Silicone | -40~220 | Transparence | ||

100 | 25,30,50 | 3~100 | Silicone | -40~220 | Transparence | ||

PET plating film (Blue) | |||||

Thickness | Adhesive | Adhesive types | Temperature range | Color | Features and applications |

μm | g/25mm | ℃ | |||

30 | 10~100 | Acrylic | -40~120 | Transparence | High temperature, corrosion, plating for PCB board |

40 | 10~120 | Acrylic | -40~120 | Transparence | |

50 | 10~270 | Acrylic | -40~120 | Transparence | |

60 | 10~270 | Acrylic | -40~120 | Transparence | |

80 | 10~270 | Acrylic | -40~120 | Transparence | |

100 | 10~270 | Acrylic | -40~120 | Transparence | |

125 | 10~270 | Acrylic | -40~120 | Transparence | |

150 | 10~270 | Acrylic | -40~120 | Transparence | |

188 | 10~270 | Acrylic | -40~120 | Transparence | |

PET Black shading film | |||||

Thickness | Adhesive | Adhesive types | Temperature range | Color | Features and applications |

μm | g/25mm | ℃ | |||

30 | 10~100 | Acrylic | -40~120 | black |

Properties and Uses: 1, black cover is good. Color uniformity, permanent, bright and smooth surface. 2, has good mechanical properties and thermal stability. 3 for black slip of paper tape, audio equipment, tape. Black PET film Category: Black PET film is divided into translucent and opaque in two sizes, standard thickness series: 25UM ~ 250UM width 1000MM, also according to customer requirements cut into various widths. |

40 | 10~120 | Acrylic | -40~120 | black | |

50 | 10~270 | Acrylic | -40~120 | black | |

60 | 10~270 | Acrylic | -40~120 | black | |

80 | 10~270 | Acrylic | -40~120 | black | |

100 | 10~270 | Acrylic | -40~120 | black | |

125 | 10~270 | Acrylic | -40~120 | black | |

150 | 10~270 | Acrylic | -40~120 | black | |

188 | 10~270 | Acrylic | -40~120 | black | |

- Previous product:High-temperature PET film (Golden ) Next Product:4 layer transparence PET film

中文

中文 English

English Vietnamese

Vietnamese

Email

Email Hot line

Hot line