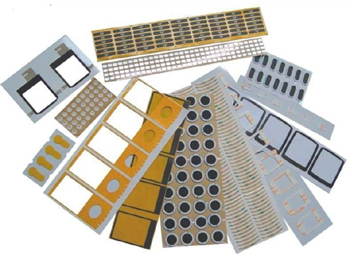

Release paper (release papers), also known as the release paper, release paper, silicone paper. Preventing adhesion is a prepreg, and the prepreg can protect from contamination of release paper. Release paper should meet: to stick to the prepreg, but easy to make separation of the two; chemical reaction or contaminate the resin system does not react with the resin system; when the ambient temperature and humidity changes, release paper length and width should be remain unchanged, in order to avoid leaving the release paper creping folds prepreg; should be sufficiently dense, it can prevent passage of moisture into the prepreg; elongation after the release paper to be towed with the fibers consistency, to prevent the prepreg during preparation due to the drawing is not synchronized to cause deformation or distortion; its thickness, is not easy to precisely control the mass per unit area.

General color:Blue, white, yellow, etc.

General thickness: ranging from 35 g / m2 to 250 g / m2 (can be higher).

General Release Force: 3 ~ 2000 gf / 25mm customized

Release Paper Category

1 .PE coating release paper:

After PE coating on paper, the surface coat with silicone oil, derived from the production of release paper.According to the structure can be divided into:

l One side coate with plastic and silicone oil,

l double sides coate with plastic and single side coated with silicone oil,

l double sides coate with plastic and silicone oil,

2 .GLASSINE release paper

After the glassine paper coated by the overpressure from the type agent production obtained after the release paper, according to the structure can be divided into single-sided and double-sided release release.

Because after supercalendered glassine paper firmness good, especially for die-processing plants.

3 .CCK release paper

CCK paper surface is coated with a layer of special clay was applied after the release agent, derived from the production of release paper can be divided into single-sided and double-sided release release

Especially because of its high temperature resistance, and it is widely used in the carbon fiber industry.

Release paper selection parameters need to focus on:

1. Cleanliness: refers to the use of environmental cleanliness requirements

2, from the type of power: refers to the degree of release paper from the type, at this point there is no absolute value, to see a different recipe each manufacturer to decide.

3, thickness: the thickness of the product will affect the die, so also need to be considered.

Release paper has the following technical indicators, dry coating amount of silicon at room temperature peel strength, aging peel strength and residual adhesion rate.

Applicable industries: electronics, automotive foam, printing, etc., and most of its use sticky together, particularly tape, so the general use of the product will be used to tape releasepaper

- Previous product:没有了! Next Product:没有了!

中文

中文 English

English Vietnamese

Vietnamese

Email

Email Hot line

Hot line